- Address

- Rm B306, Build A, RunFengYuan Business Center, Block 74, Baoan District , Shenzhen , China

- Phone

- 86-13534206421 / 86-0755-27788210

- nicolas.liu@samtronik.com

| Categories | Other Equipment |

|---|---|

| Brand | SAMTRONIK |

| Model | AT200/AT300/AT400 |

| Moving speed(XYZ) | 0.1-800mm/sec |

| I/O signal | 6 In puts / 6 Out puts |

| Repetitive accuracy | ±0.02mm |

| Update Time | Apr 18,2025 |

Automatic

dispensing machine

1)

Replace manual dispensing operation to realize mechanized production.

2)

High-precision three-axis platform, using imported brands, to ensure the

accuracy and stability of equipment.

3)

Professional operating software to simplify dispensing.

4)

Super high performance-price ratio, with the lowest cost to achieve intelligent

dispensing.

5)

Intelligent and simple operation interface.

6)

Program files can be uploaded or downloaded through U-disk to facilitate data

management and preservation.

7)

Running in silent state, it will not cause noise pollution to the production

site. It is suitable for

8)

Products that need to be glued in various industries.

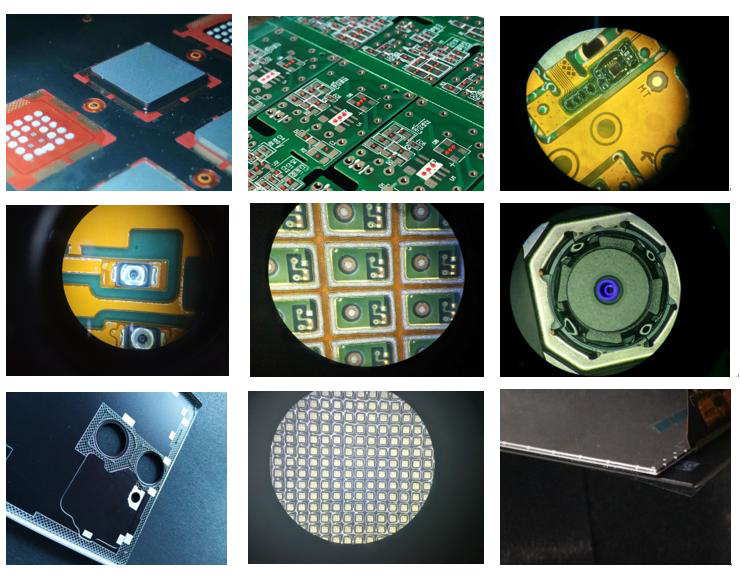

|

LED Packaging |

LCD

glass laminate sealant |

Speaker

dispensing |

|

Coating

of Automobile Parts |

Quantitative

liquid filling coating |

Power

Parts Packaging |

|

Fixing

and Protection of PCB Electronic Parts |

Mobile

phone panel dispensing or button dispensing |

Point

glue sealing of battery box |

|

Hardware

parts dispensing bonding |

Chip

binding |

Semiconductor

Packaging |

|

Mobile

phone panel dispensing or button dispensing |

Point

glue sealing of battery box |

Hardware

parts dispensing bonding |

|

Chip

binding |

Semiconductor

Packaging |

|

specifications:

|

Model |

AT200 |

AT300 |

AT400 |

|

Range of travel(X*Y*Z)(mm) |

200*200*100 |

300*300*100 |

400*350*100 |

|

Dimension(W*H*D) (mm) |

350*650*750 |

750*800*750 |

750*800*750 |

|

Maximum desktop load |

10KG |

||

|

Moving speed(XYZ) |

0.1-800mm/sec |

||

|

Repetitive accuracy |

±0.02mm |

||

|

Program Recording

Capacity |

1000 groups, each group 4000 points (support U disk) |

||

|

Motor system |

Micro-stepping motor |

||

|

Motion Mode |

Point to Point, Connecting Line Section |

||

|

Driving mode |

Motor + Precision Screw + Slider |

||

|

Motion compensation

function |

3 Axis (any route in 3 D space) |

||

|

Edit Model |

Instruction Box or Computer File Input |

||

|

I/Osignal |

6 In puts / 6 Out puts |

||

|

Input power supply |

AC220V |

||