- Address

- Rm B306, Build A, RunFengYuan Business Center, Block 74, Baoan District , Shenzhen , China

- Phone

- 86-13534206421 / 86-0755-27788210

- nicolas.liu@samtronik.com

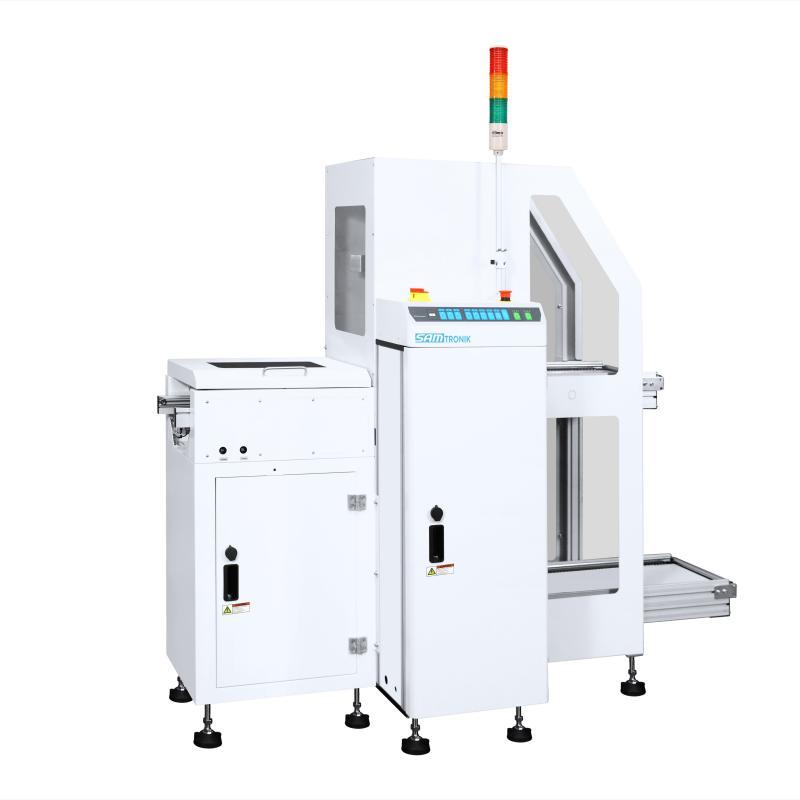

SM-2B101-Magazine Unloader(European type)

Description:

1. The machine is used for the back end of the production line body and automatically unloads PCB.

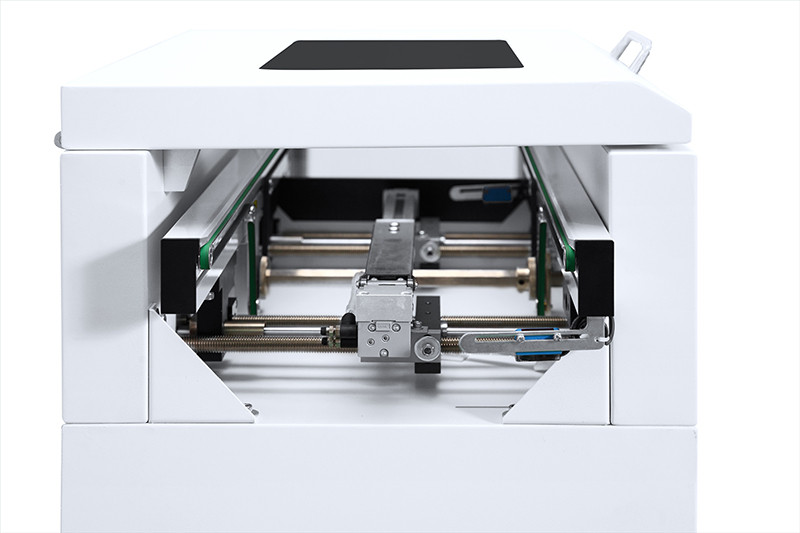

2. It is transported vertically through the humping and pushing device and lifting, and then it is sent to the material box with the pushing mechanism.

3. The machine is characterized by short cycle time, labor-saving handling action, achieving the best intelligent production effect, improving quality and production efficiency.

4. Electrostatic powder coating is applied on the surface of the machine. The frame adopts the perfect combination of European standard profile and sheet metal to ensure the process stability and excellent durability.

Feature:

1. The results of European standard aluminum profile + steel plate frame make the weighted design structure stronger.

2. Frequency conversion lifting device, stable action, anti card design

3. Export oriented, simple width adjustment design, quick and flexible line change

4. Push in structure strength can be adjusted flexibly

5. Touch type membrane panel

6. 4-point positioning of material box

7. Design of the highest safety level of CE

8. High throughput, short transfer time of material box

Specification :

|

Configuration |

M |

L |

LL |

XL |

|

Transmission height |

910mm±30mm |

910mm±30mm |

910mm±30mm |

910mm±30mm |

|

Conveyor belt |

3MM Flat belt |

3MM Flat belt |

3MM Flat belt |

3MM Flat belt |

|

Interface |

SMEMA |

SMEMA |

SMEMA |

SMEMA |

|

Transmission direction |

Left to right / right to left (optional) |

|||

|

Fixed guide rail |

Front part of machine |

|||

|

Transmission composition |

1-segment |

1-segment |

1-segment |

1-segment |

|

Width adjustment mode |

Manual adjustment |

|||

|

PCB size |

|

|

|

|

|

Material frame size |

355*320* 563mm |

460*400* 563mm |

535*460* 570mm |

535*530* 570mm |

|

Material frame quantity |

Upper 1, Lower 2 |

Upper 1, Lower 2 |

Upper 1, Lower 2 |

Upper 1, Lower 2 |

|

PCB size(L*W) |

80*70mm~ 330*250mm |

80*70mm~ 445*330mm |

80*70mm~ 530*390mm |

80*70mm~ 530*460mm |

|

PCB thickness |

0.7~4.0mm |

0.7~4.0mm |

0.7~4.0mm |

0.7~4.0mm |

|

PCB component height |

±30mm |

±30mm |

±30mm |

±30mm |

|

PCB weight |

≤1.5KG |

≤1.5KG |

≤1.5KG |

≤1.5KG |

|

Installation requirements |

|

|

|

|

|

Power Supply |

220V 50/60HZ ±10% |

220V 50/60HZ ±10% |

220V 50/60HZ ±10% |

220V 50/60HZ ±10% |

|

Power supply system |

L1+N+PE |

L1+N+PE |

L1+N+PE |

L1+N+PE |

|

Power |

0.5KW |

0.5KW |

0.5KW |

0.5KW |

|

Gas source |

0.6MPa |

0.6MPa |

0.6MPa |

0.6MPa |

|

Air consumption |

<20L/min |

<20L/min |

<20L/min |

<20L/min |

|

Power plug type |

European standard, American Standard, British standard...

(optional) |

|||

|

Machine description |

|

|

|

|

|

L*W*H |

1898*766* 1630mm |

2457*845* 1630mm |

2632*900* 1630mm |

2632*973* 1630mm |

|

Machine weight |

210kg |

250kg |

290kg |

310kg |

|

Fixed point to front dimension

(x) |

375mm |

375mm |

375mm |

375mm |

|

Noise level |

<75 dB |

<75 dB |

<75 dB |

<75 dB |

Option:

A-single machine automatic width adjustment

B- attend to board system system

C-fuji Nexim, Panasonic ilnb system docking

D-ce security interlock

E-AGV docking

F-number of boxes

G- other