- Address

- Rm B306, Build A, RunFengYuan Business Center, Block 74, Baoan District , Shenzhen , China

- Phone

- 86-13534206421 / 86-0755-27788210

- nicolas.liu@samtronik.com

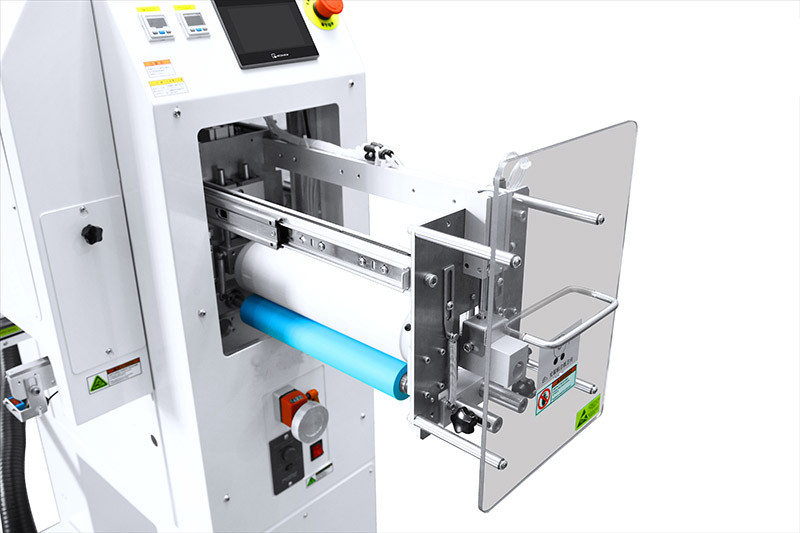

SM-1A050-PCB Surface Cleaning Machine for smt line

The necessity of using PCB cleaner/PCB Surface Cleaning Machine

1. Dust and dirt may be stuck on the surface of PCB during the handling, laser marking and parking of PCB.

2. The static electricity on the PCB surface causes the PCB to absorb dust.

3. SMT components will become smaller and smaller, and small stains may affect the welding effect.

4. Some large stains may cause short circuit or potential defects of the solder joint.

5. At present, many customers use high-pressure air to clean PCB surface, which has become a fact with high noise, high energy consumption, secondary air pollution, etc.

6. Before and in the future, cleaning and removing static electricity on the surface of PCB chip money will become a part of the process.

Description:

1. Contact cleaning is more durable and clean, mainly to deal with dust pollution on PCB surface

2. Special structure, effectively clean 99% visible pollutants on PCB surface

3. The latest electrostatic removal technology, positive and negative ions exceed the industry standard

4. Newly developed anti-static brush dedusting device

5. Newly developed anti-static roller dust adhering device

6. Dust adhering

paper roll: special polymer material has anti-static function

7. The best adhesive coating thickness improves the foreign body daughter-in-law and catching power

8. Support real-time monitoring of electrostatic pressure

9. Alarm device for blockage of foreign matters in pipeline of vacuum dust collection system

10. Provide and develop relevant interfaces for MES and external system docking

11. CE highest safety level design

12, specially

customized for SMT mounting

Feature:

1. Dust sticking system

Japan imported high-precision anti-static sticky roller, contact cleaning, the effect is more thorough and lasting.

When the static electricity reaches 1kV, the normal speed is reduced to below 50v-100v through the PCB cleaning function to prevent the damage of static electricity to electronic components. The static electricity elimination speed is the world leader.

2. Brush dedusting system

The special antistatic brush imported from Japan is equipped with four layers of air filter discharge of vacuum dust extraction system to prevent secondary pollution in the air.

Mechanical dust extraction design is convenient for refueling and maintenance.

Many years of professional surface cleaning design and production experience, we know more about the details of customer requirements.

3. Polymer dust

Sticky dust paper roll: special polymer material with antistatic function, the best thickness of adhesive coating.

Improve the absorption and catching power of foreign matters.

No cutting, easy to use, very safe, save time, minimize waste and save 20%.

4. Electrostatic pressure monitoring system

Online electrostatic real-time monitoring can be customized according to customer needs.

Monitoring data can be recorded online with touch screen at the same time.

The monitoring voltage range can be set.

Dual loop monitoring supports audible and visual alarms.

With the industry-leading surface electrostatic monitoring sensor,

Different

cleaning modes can be easily selected according to different substrates.

Specification :

|

Configuration |

M |

L |

LL |

|

Transmission height |

910mm±30mm |

910mm±30mm |

910mm±30mm |

|

Conveyor belt |

3MM Flat belt |

3MM Flat belt |

3MM Flat belt |

|

Interface |

SMEMA |

SMEMA |

SMEMA |

|

Transmission direction |

Left to right / right to left (optional) |

||

|

Fixed guide rail |

Front part of machine |

||

|

Transmission composition |

1-segment |

1-segment |

1-segment |

|

Width adjustment mode |

Manual adjustment |

||

|

PCB size |

|

|

|

|

PCB size(L*W) |

70*70mm~500* 250mm |

70*70mm~500* 330mm |

70*70mm~530* 460mm |

|

PCB thickness |

0.6~4.0mm |

0.6~4.0mm |

0.6~4.0mm |

|

PCB component height |

A 0MM/B 35mm |

A 0MM/B 35mm |

A 0MM/B 35mm |

|

PCB weight |

≤1.5KG |

≤1.5KG |

≤1.5KG |

|

Cleaning & electrostatic system |

|

|

|

|

Cleaning method |

Brush + vacuum + electrostatic removal + dusting roller + dust collection

roll + electrostatic removal + monitoring system (shape support upload) |

||

|

Sticky dust and dust collection |

2 + 1 / antistatic special material |

||

|

Dust removal brush |

Antistatic special material |

||

|

Antistatic device |

1 set for each inlet / outlet |

||

|

Vacuum recovery |

Foreign matter blocking alarm device |

||

|

Installation requirements |

|

|

|

|

Power Supply |

220V 50/60HZ ±10% |

220V 50/60HZ ±10% |

220V 50/60HZ ±10% |

|

Power supply system |

L1+N+PE |

L1+N+PE |

L1+N+PE |

|

Power |

0.1KW |

0.1KW |

0.1KW |

|

Gas source |

0.6MPa |

0.6MPa |

0.6MPa |

|

Air consumption |

<10L/min |

<10L/min |

<10L/min |

|

Power plug type |

European standard, American Standard, British standard...

(optional) |

||

|

Machine description |

|

|

|

|

L*W*H |

550*688* 1380mm |

550*788* 1380mm |

550*978* 1380mm |

|

Machine weight |

130kg |

150kg |

180kg |

|

Fixed point to front dimension

(x) |

185mm |

185mm |

185mm |

|

Noise level |

<75 dB |

<75 dB |

<75 dB |

Option:

A-single machine automatic width adjustment

B- attend to board system system

C-fuji Nexim, Panasonic ilnb system docking

D-ce security interlock

E- Electrostatic monitoring system

F- Air pressure monitoring system

G- Anti PCB warping device

H- other